The method of Streltsov's of improvement of 3D printer, |

|

|

|

|

|

|

|

|

The invention concerns to technology of 3D printer, intended for manufacturing the metallic products of the complex form. |

|

|

Point 1. Difference of the declared invention from the existing analogues be so, what instead of the laser, which has low coefficient of efficiency (usually in the laser in radiation will be transformed about 20 % of brought energy, the all other portion of energy turn into heat and will useless dissipates), is used the injector, developed by experts of the Japanese firm "NAKAYAMA STEEL WORKS, LTD", which they used for covering by the amorphous metal film of crankshaft of motor vehicles (the patent of Japan # 4579317). The specified injector in process of fusion of metal has greater coefficient of efficiency in comparison with the laser (the most part of the energy brought to an injector, we passed on fusion of metal or already the fused metal be move to injector), what will allow to lower energy expenses at creation of metal products in the 3D printer. This injector has the narrow (dot) diagram of sprinkling of the fused metal, what in aggregate quite allows him to compete in the 3D printer with the laser at manufacturing of bulky metal products of a low class of accuracy. |

|

|

|

|

|

|

|

|

|

|

|

then we can hope, that at use of a similar atomizer in 3D printer and selection of the certain technological modes it will be possible to receive thick metal 3D products of the complex form with amorphous structure of an allocation of atoms.. (As it is known, that metals with amorphous structure of an arrangement of atoms are not subject to corrosion and possess strength characteristics in some times best by comparison with traditional metal products with a crystal lattice). |

|

|

Point 2. A method have such different that instead of the laser (of the focusing injector, which described in the patent # 4578317 Jp) in the 3D printer we use a ultrasonic electro arc focusing atomizer, his prototype I described in own application for the invention from 2003. |

|

|

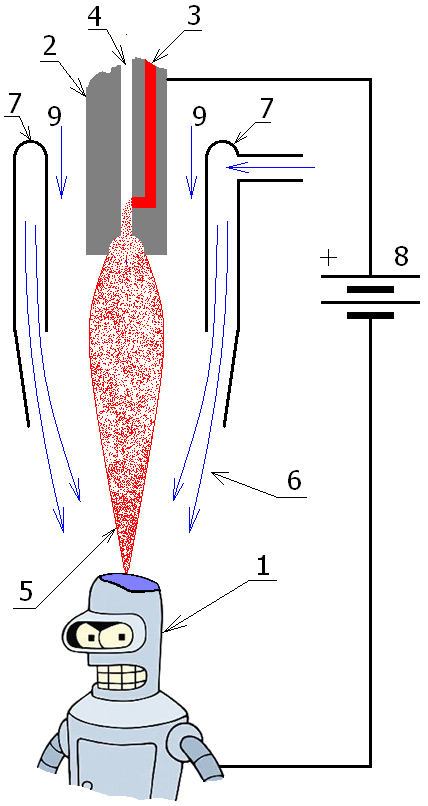

For this purpose in an atmosphere of inert gas (for example, argon) an atomizer, having on an axis the hollow channel, connect to a positive pole of the electric power supply, a metal substrate of the future product connect to a negative pole of the electric power supply. Later we provoke ultrasonic fluctuations of an atomizer. Along the axial channel of an atomizer we pump preliminary fused metal which after an output from the channel of an atomizer is sprayed under action of ultrasonic fluctuations. Between an atomizer and a substrate will arise an electric arc. In addition to ultrasonic dispersion also is possible and the organization of spraying metal by gas - by means of argon or other inert gas. The liquid drops of the fused metal by reason of thermionic emission and losses electrons get a positive electric charge and fly aside negatively charged product, getting an additional warming up in the electric arc. Besides it the gas stream will blow a drop of the fused metal from atomizer in the direction of a product, and if necessary we can also use and the gravitational field of the Earth. Around of an atomizer the focusing cylindrical nozzle, similar to those which is described in the Japanese patent # 4579317 Jp is established.

The general scheme of a ultrasonic atomizer with focusing is on a image: |

|

|

|

|

|

|

|

The similar electroarc atomizer will allow to make on the 3D-printer of complex metal products with smaller quantity of oxides in comparison with the method, described in Point # 1. Probably, given method will allow to make volumetric metal products of the complex form with amorphous structure of an allocated atoms, if we will QUICKLY serially spray THIN layers of metal. |

|

|

Also it is quite probable, what by means of the technology, which will similar described here, it will be possible to receive in 3D the printer of a product from refractory metals. For these purposes, however, will have to use plasmatron with a focusing nozzle, and as "ink" a powder of refractory metal. |

|

|

Thus, replacement in the 3D printer of the laser by the spraying atomizers (or their joint, serial use) gives following advantages:

1) the economy of energy (cost of products can will decrease to such degree, that manufacturing of details can appear economic expedient not only for prototyping, but also for serial industrial production) 2) the improvement of strength characteristics of products 3) tears off prospect of manufacturing of volumetric complex details from amorphous metal alloys. |

|

|

|

|